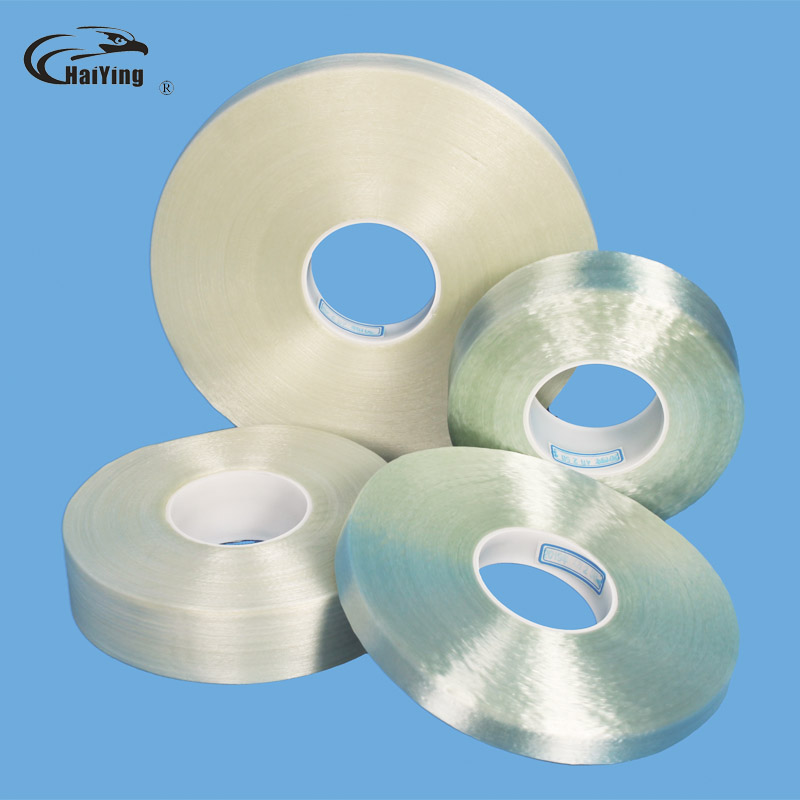

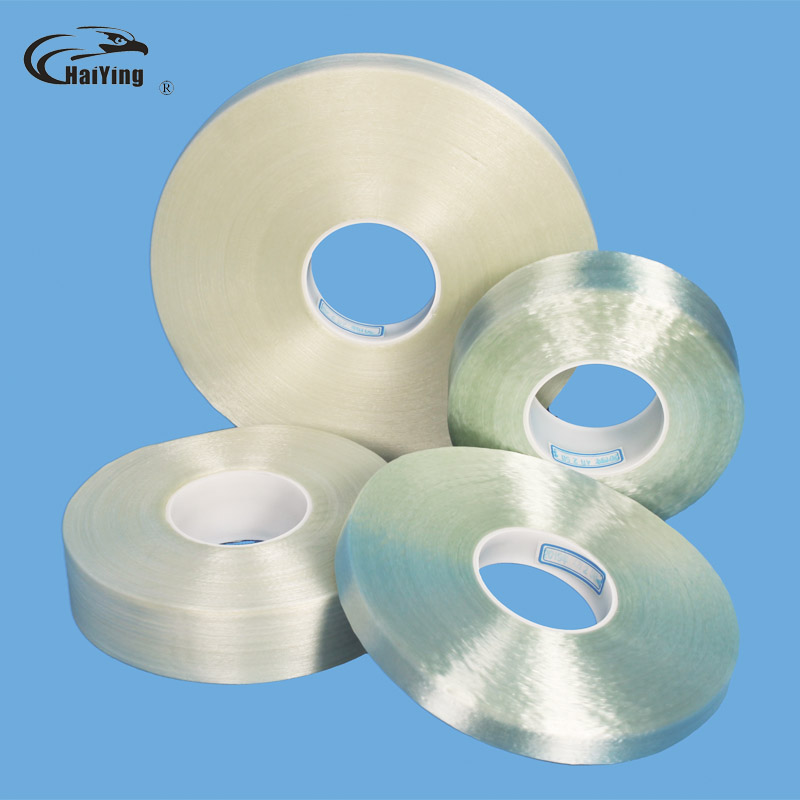

Polyester Resin Impregnated Fiberglass Web Banding Tape

|

Introduction:

"HaiYing"H180, F155,B130 banding tapes

consist of parallel twisted E-glass yarns preimpregnated with a special

thermosetting polyester resin. The banding tape is pliable and tacky. Its web

structure provides easy unwind without glass strands separation and

overlapping.The product contributes the characteristics of high tensile

strength, high resistance to shocks, high modulus of elasticity, dimensional

stability as well as no magnetically confining and eddy currents losses,

which can be widely used as ideal banding materials for electrical motors,

transformers and lightening arresters.

|

|

Properties:

|

|

Type

|

2850-W

|

2841-W

|

2830

|

|

Thermal class

|

H

|

F

|

B

|

|

Volatile content

|

≤2%

|

≤4%

|

≤5%

|

|

Loss of weight at calcination

|

27%±2%

|

27%±2%

|

27%±2%

|

|

Soluble resin content

|

≥90%

|

≥90%

|

≥90%

|

|

Tensile strength before curing

|

≥1500N/cm

|

≥1000N/cm

|

≥500N/cm(0.17mmT)

|

|

Maximum pull while banding

|

1000N/cm

|

1000N/cm

|

400N/cm

|

|

|

Specification:

|

|

Thickness (mm)

|

Width (mm)

|

Length (M/pancake)

|

|

0.17

|

10,15,20,25,30

|

100,150,200,250

|

|

50

|

100

|

|

0.3/0.33

|

10,15,20,25,30

|

200

|

|

50

|

100

|

|

|

*

Special specification and package are availabe upon request, (such as spool)

|

|

Curing cycles:

|

|

Temperature (℃)

|

160

|

150

|

135

|

120

|

115

|

|

Time (hour)

|

5

|

6.5

|

10

|

16

|

24

|

|

|

*

The above times do not include the time for the workpiece to reach the curing

temperature.

|

|

Storage stabili:

|

|

Storage temperture ℃

|

10

|

15

|

20

|

30

|

|

Time (month)

|

12

|

10

|

6

|

3

|

|

|

|

|

Application

Instruction of Banding Tape

|

|

|

|

Application

1、Banding tape should be

stored in the condition of room temperature. If environment temperature is

above 30℃, the products should be put in the freezer.

2、The testing of properties (for example: test

volatile content) should be carried within one hour after the banding tape is

taken from the plastic bag.

3、When applying the banding tape, keep it in the

plastic bag at the room temperature for 24 hours after taking out from the

freezer.

4、During the process of application, uneven tension

and unsmooth banding would make the tape separation. You could continue to

use after neatening the remaining pancake.

5、Banding process should proceed at the room

temperature. Better effect will obtain if the process is put up at the heat

condition.

Heat banding process is as follows:

A.Preheat the work piece at the temperature 80℃ for one hour.

B. Prereheat the banding tape at the temperature 40℃±5℃ for 20 minutes. Preheat can not be over

the time to avoid the tape to be cured in advance,. The tape preheated should

be used up once.

6、Certain tension should be applied to the banding

tape. Tension is less than 1000N/cm for 0.30mm thick tape , The speed is good

enough at 10m-15m /min.

7、 In order to prevent the loosen of the tape, its

end should be locked when the banding work finished. Insert the end into

inner layer of the tape and press tightly.

8、It is recommended to cure the finished banding work

piece continuely at several stage: 80℃ for 1 hour;

120℃ for 1 hour; 155℃ for 3 -

4 hours. It needs 6 hours for tractor motor and industrial large motor (

above-mentioned exclude the time for work piece to reach the curing

temperature).

9、 If you would treat dry process of varnish dipping

and curing of banding tape together, it is necessary to do a trial to make

sure that the dry process will not affect the curing of banding tape.

10、If you want banding process by hands, richer resin

and higher volatile content type tape than normal of ours is suitable for

you.

|

|

|

|

|

|

|

Banding Motor Rotor

|

Spool Package

|

Banding Lightning Arrester

|

|

|

|

|

Banding Machine

|

Banding Transformer Coil

|

Banding Reactor

|

|

|

|